The Role Of China Scaffolding Coupler In Construction Projects

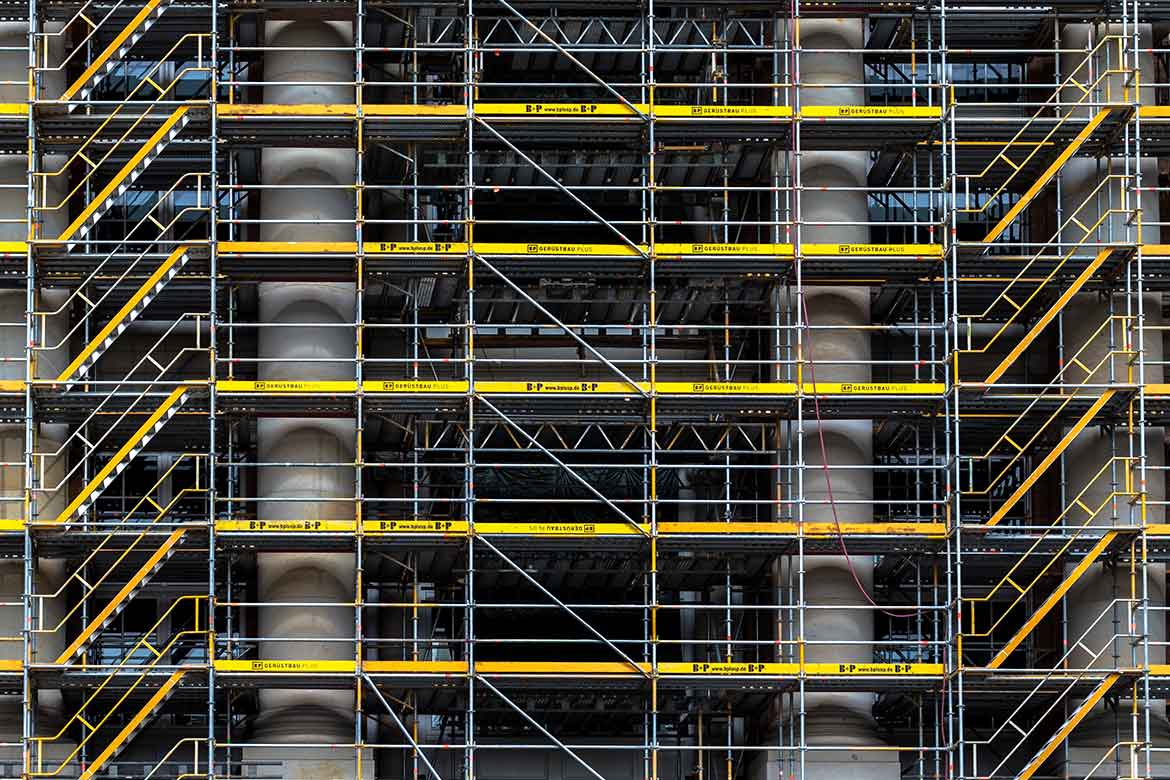

China has emerged as a leading manufacturer and exporter of scaffolding couplers, essential components in the construction industry. Scaffolding couplers are connectors that hold together scaffold tubes, providing stability and safety for workers on construction sites. These couplers are made from high-quality materials like forged steel or ductile iron, ensuring durability and reliability under heavy loads. China's scaffolding couplers are known for their precision engineering, adherence to international safety standards, and cost-effectiveness.

They come in various types such as swivel couplers, sleeve couplers, putlog couplers, and girder couplers, each designed for specific applications.

China scaffolding couplers play a crucial role in construction projects by providing stability and safety to the overall structure. These couplers are essential components that connect scaffolding tubes, ensuring a secure and reliable framework for workers to perform their tasks at elevated heights. With their durable construction and precise engineering, China scaffolding couplers offer excellent load-bearing capacity, enabling the safe transfer of weight across multiple levels.

Key Features And Advantages Of China Scaffolding Coupler

China scaffolding couplers offer a range of key features and advantages that make them an ideal choice for construction projects. Firstly, these couplers are manufactured using high-quality materials, ensuring durability and long-lasting performance. They are designed to securely connect scaffold tubes, providing a strong and stable structure. Another notable feature is their versatility. China scaffolding couplers come in various types, such as swivel, fixed, sleeve, or putlog couplers, allowing for flexible configurations to meet different project requirements.

Moreover, these couplers are easy to install and dismantle, saving time and effort during construction processes. Their precision design ensures a tight connection between tubes while maintaining safety standards.

Safety Considerations For Using China Scaffolding Coupler

When using China scaffolding couplers, it is crucial to prioritize safety measures. Firstly, ensure that the couplers are made from high-quality materials and meet the relevant industry standards. Inspect them regularly for any signs of wear or damage. Proper installation is paramount to guarantee stability and load-bearing capacity. Ensure that each coupler is securely attached to the scaffold tube, using the correct tightening torque as specified by the manufacturer.

Regular inspections should be conducted during use to identify any potential issues such as loose connections or bent couplers. Additionally, workers should be trained on safe assembly and dismantling procedures, including proper use of personal protective equipment.

Choosing The Right China Scaffolding Coupler For Your Project

When it comes to scaffolding, selecting the appropriate coupler is crucial for ensuring safety and stability. ADTOMALL, as a leading scaffolding coupler manufacturer in China, can be one of your choices. In China, where scaffolding is widely used in construction projects, there are various types of couplers available. The first step in choosing the right coupler is understanding the specific requirements of your project. Consider factors such as load capacity, compatibility with existing scaffolding systems, and ease of installation.

评论

发表评论