How to Ensure the Stability of Octagonal Scaffolding in Use?

To ensure the stability of octagonal scaffolding during use, the following steps are crucial:

1. Foundation Preparation

Level Ground: The scaffolding should be erected on a level and firm surface. Use a spirit level to ensure that the ground is as flat as possible. Any unevenness can cause the scaffolding to tip or become unstable. If the ground is sloped, it may be necessary to use leveling pads or shims under the base plates of the scaffolding to correct the slope.

Suitable Base Material: In soft or unstable ground conditions, such as sandy or muddy areas, it's essential to provide a solid base. This can be achieved by laying down concrete slabs, timber mats, or other load - bearing materials. These materials help to distribute the weight of the scaffolding over a larger area and prevent the legs of the scaffolding from sinking into the ground.

2. Component Assembly and Connection

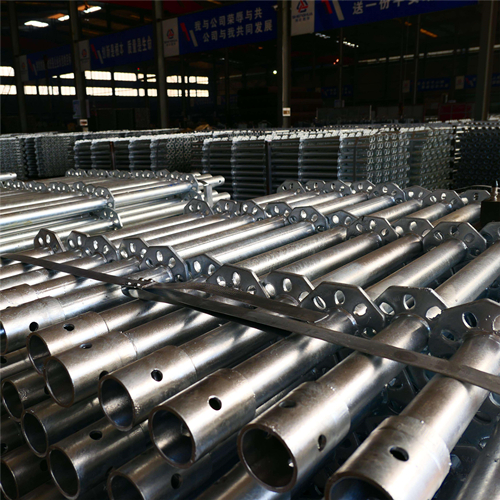

Proper Fit of Components: Ensure that all the poles, braces, and connectors of the octagonal scaffolding fit together correctly. The poles should be inserted fully into the connectors, and any locking mechanisms, such as pins or clips, should be engaged properly. A loose or misaligned connection can lead to a weak point in the structure.

Tightening of Connections: Use the appropriate tools to tighten bolts, nuts, and other fastening devices. The connections should be snug but not over - tightened to the point of damaging the components. For example, when using bolted connections, follow the recommended torque settings to ensure a secure and stable joint.

Diagonal Bracing: Install diagonal braces correctly. Diagonal braces play a vital role in providing lateral stability to the octagonal scaffolding. They should be attached at the appropriate angles and tensioned properly. The braces form a triangular structure with the vertical and horizontal members, which is a fundamental geometric shape for stability.

3. Load Management

Know the Load Capacity: Be aware of the maximum load - bearing capacity of the octagonal scaffolding. This information is usually provided by the manufacturer. Do not exceed this capacity to avoid overloading the structure. The load capacity takes into account the weight of workers, tools, and materials.

Even Distribution of Loads: Distribute the loads evenly across the scaffolding. Avoid concentrating heavy loads in one area or on one side of the octagonal structure. For example, when storing materials, spread them out over the platforms rather than piling them up in one corner.

Limit Dynamic Loads: Minimize sudden or dynamic loads. Workers should avoid jumping or dropping heavy objects onto the scaffolding. These actions can create shock waves that put additional stress on the structure and potentially lead to instability.

4. Regular Inspection and Maintenance

Pre-Use Inspection: Before each use, conduct a thorough inspection of the scaffolding. Check for any damaged or missing components, such as bent poles, cracked connectors, or loose braces. Any issues should be repaired or replaced immediately.

During-Use Checks: Periodically during use, visually inspect the scaffolding for signs of movement, sagging, or unusual noises. If any such signs are detected, stop work immediately and assess the stability of the structure.

Weather Considerations: In windy or stormy weather conditions, take extra precautions. High winds can exert significant lateral forces on the scaffolding. If possible, secure the scaffolding more firmly to the building or use additional guy wires to enhance stability. Also, after exposure to wet weather, check for any signs of corrosion or water damage that could affect the structural integrity.

评论

发表评论